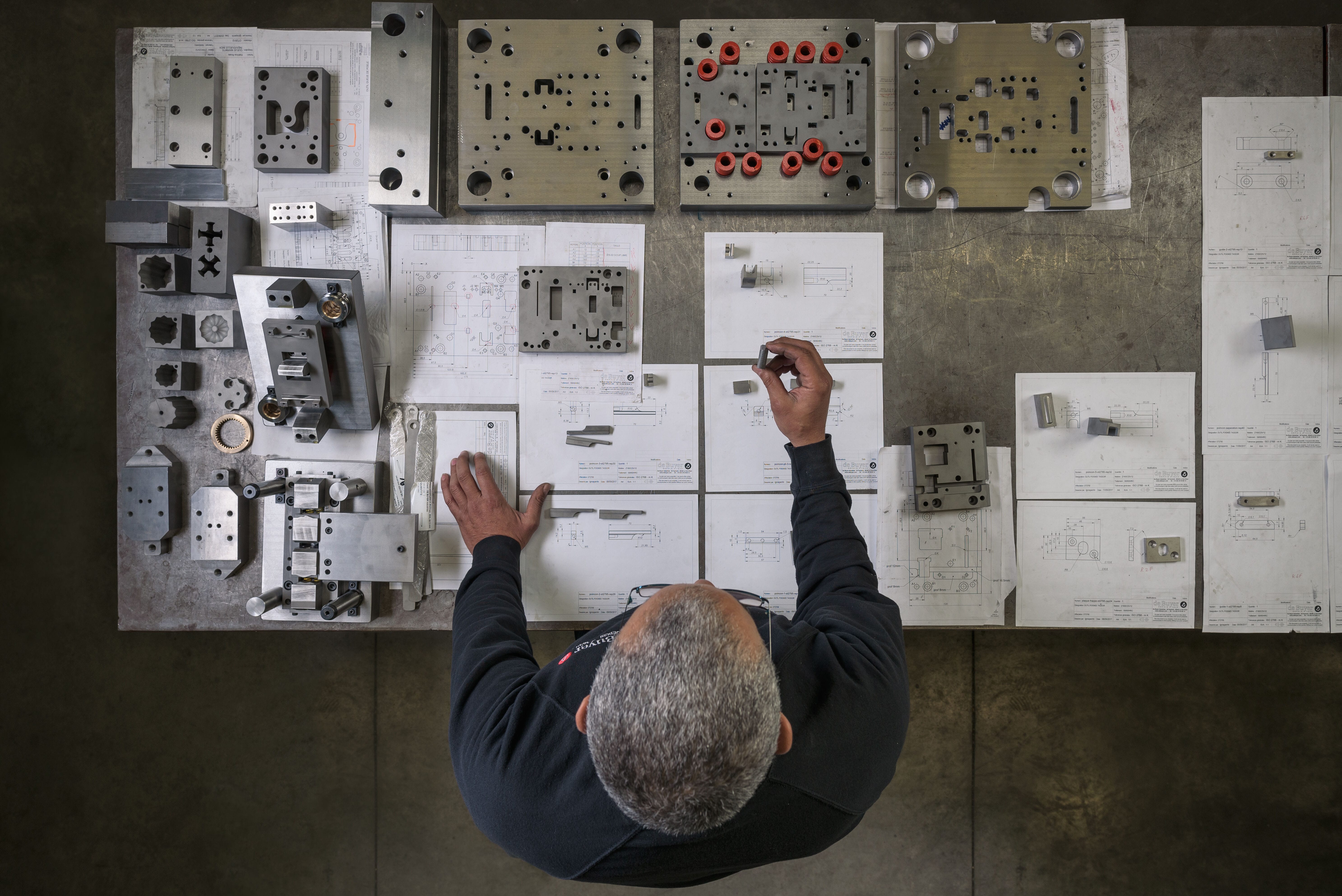

Our know-how

The spirit of innovation

De Buyer develops solutions that are both smart and functional. The company often works with professionals in the culinary field as part of the product design process. These real-life technical challenges help to develop the de Buyer’s firm’s knowledge and expertise and feed its employees’ passion for their work.

This spirit of innovation is also characterised by a real-life approach to design: the products are tested in a professional kitchen by both a chef and an R&D team to gauge their performance and to meet chefs’ high expectations as far as possible.

In order to innovate, the company combines versatile human skills with technology. This enables it to adapt to specific requests, even when they require a ‘custom’ approach.

Designed and made in France

To reach the level of excellence required by culinary professionals, de Buyer strives to create superior products that are durable and technical in design to ensure precision of use. French cooking places great importance on the high quality of the tools used.

De Buyer’s secret also lies in the skill of its ‘artisans’, in much the same way as within the culinary field. Manual skills are sometimes required in the manufacturing process to perfect the finish of the products. Each artisan pays great attention to detail, conscious of the fact that they are contributing to a great culinary tradition.

De Buyer manufactures the majority of its products in its factory in Vosges. This allows the company to take full control of the production process and guarantee quality.

A culture of fine work

and durability for guaranteed precision

At de Buyer, every type of saucepan, knife, kitchen or baking utensil is subject to a meticulous design process which is evident in the quality of the final product. This is testament to its performance and constitutes a guarantee of success for the most demanding of cooks.

When it comes to frying pans and saucepans, a good product is one that is well finished, made with high-quality material and custom components and has a simple but elegant design.

Our copper saucepans are particularly carefully finished; the skilled hands of the artisan make all the difference! The manual polishing process brings out the copper’s golden shine.

This culture of fine work is also expressed through the weight of certain products, such as the steel frying pans. They feel solid in the hand, lending the product authentic character. The handles are riveted for unwavering support; they are curved French-style; and they are ergonomically designed to ensure a firm grip.

Ingenuity and creativity

As for baking utensils, the ingenuity of the techniques used is second only to the creativity of the shapes and the practicality of the product. Design is therefore just as important in the manufacture of the utensils as in the recipes that they are used for. This is particularly true of innovative products such as the GEO forme mould for pâté croûte (meat pies), developed in collaboration with Fabien Pairon, butcher-caterer MOF (best French craftsman in his field).

This culture of fine work is demonstrated by the care taken by de Buyer employees in assisting customers in the successful realisation of any recipe, be they cooking professionals or novices.

Material alchemy

De Buyer offers a complete range of saucepans, moulds, frying pans, cutlery and utensils for all the different stages involved in cooking and baking.

The company draws on tried and tested methods to manufacture its saucepans, frying pans and moulds. Its product range is based on the cooking skills required to produce honest and tasty food: copper pots for slow cooking, condensing and flaming; stainless steel for boiling and preserving; and steel for searing and grilling.

It also manufactures products necessary for baking using non-stick materials for its moulds that ensure even heat distribution.